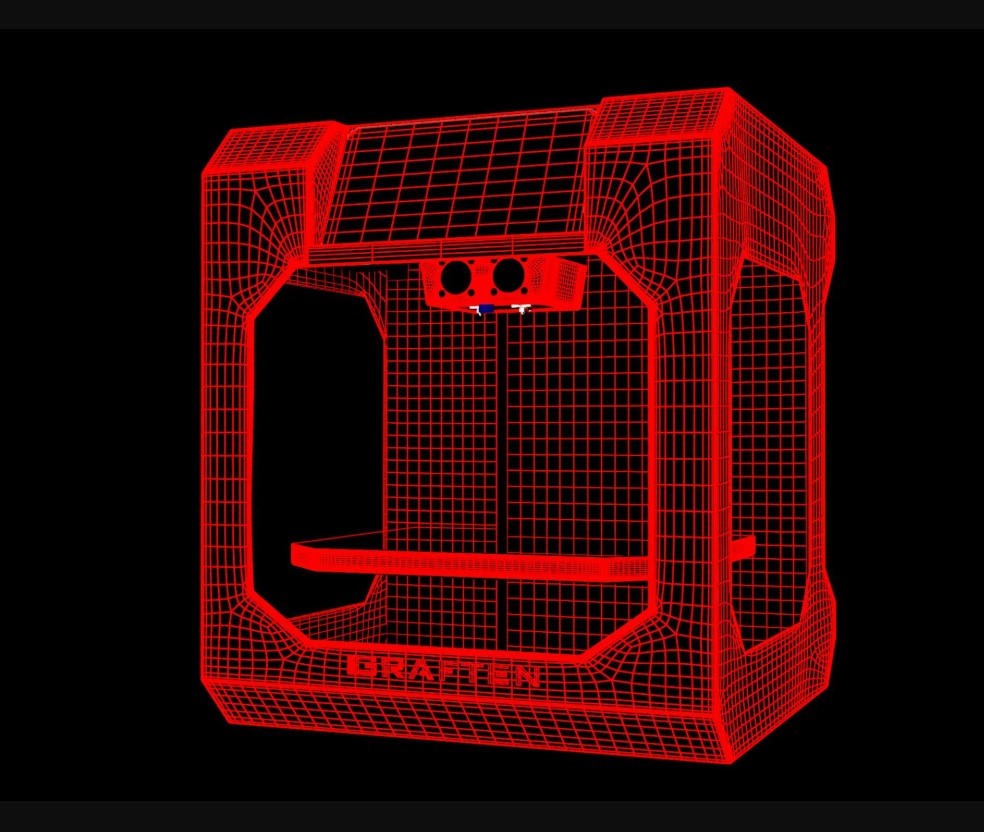

Mini PCs are notorious for running hot. They pack powerful hardware into tiny shells, and the smaller the box, the less space for airflow. But now, one clever DIY project has shown a surprisingly simple fix: replace the stock bottom cover with a 3D-printed one built for cooling.

A Fix That Doesn’t Add Bulk

Most solutions for overheating involve strapping on extra fans or propping devices up with stands. This project goes in a different direction. Instead of adding to the mini PC, it swaps out the existing bottom panel with a custom-made 3D-printed plate.

The new cover doesn’t compromise strength, according to its maker, who goes by @lixxus_3568380 online. The durability comes down to the material. Rather than the common PLA plastic found in many hobbyist prints, this design uses PETG—a stronger, more heat-resistant filament that can take the punishment of long hours under high temps.

The result is a slimmer, more practical way to push air through a mini PC without making it look like a Frankenstein mod.

Why Mini PCs Struggle With Heat

By design, mini PCs leave little room for ventilation. Their tight layouts mean that components like NVMe SSDs, CPUs, and VRMs sit close together, generating concentrated heat. Once the stock cooling solution reaches its limit, the system has no easy way to dump the excess.

That’s where this DIY solution shines. The replacement plate includes honeycomb cutouts with tapered walls, letting more air move across the internals while keeping dust buildup under control. The honeycomb design isn’t just stylish—it’s efficient, letting air escape while keeping the panel sturdy.

And anyone who’s pushed a small PC with workloads like video rendering or gaming knows how quickly throttling sets in.

Built for One Mini PC, But Adaptable

The prototype wasn’t a one-size-fits-all fix. The creator printed it specifically for the ZB-MN57 mini PC, a device that has been criticized for running hotter than average. But that doesn’t mean others can’t copy the approach.

To make it easier, the creator shared the OpenSCAD code used to design the part. That means even users without coding knowledge can tweak dimensions to match their own systems. Just swap in the right measurements, and the software will regenerate a printable model.

-

You don’t need to reinvent the wheel.

-

Just adjust values for width, depth, and screw placements.

-

Then send the model to your 3D printer.

All the necessary files are freely available on Printables, one of the most active hubs for sharing 3D-print projects.

Strength in Material Choice

What makes this design stand out is the focus on durability. PLA, the go-to for casual printing, is cheap and easy to work with, but it warps under high heat. A mini PC shell, constantly exposed to warmth, would stress it to failure.

PETG, by contrast, keeps its shape. It tolerates higher temps, resists cracking, and holds up against wear from screws and repeated handling. That’s exactly why industrial 3D projects often lean on PETG rather than PLA.

The decision to use PETG may seem small, but it’s one of the reasons the cover doesn’t feel like a cheap toy add-on.

More Than Just a Niche Fix

Not everyone has a 3D printer in their living room, and many mini PC users may never try this. But the project highlights something bigger: custom cooling through personal manufacturing. Instead of waiting for brands to fix design flaws, enthusiasts can now create their own solutions.

Mini PC makers have long been criticized for poor airflow, even as demand for small form factor machines keeps growing. Projects like this prove that hobbyists are filling gaps manufacturers leave open.

It also nudges at a bigger conversation. As 3D printers become more affordable, the line between “consumer” and “maker” blurs. For tech enthusiasts, the ability to design functional, durable parts like this cooling cover is a reminder that DIY isn’t just about aesthetics—it’s about performance.