Polyurethane foam, widely used for sealing and stabilizing mine structures, has recently been identified as a significant fire hazard. The Mine Safety and Health Administration (MSHA) has issued multiple alerts highlighting the dangers associated with its use. This article delves into the risks, recent incidents, and best practices to mitigate these hazards.

The Dangers of Polyurethane Foam

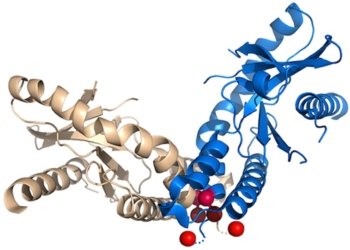

Polyurethane foam is commonly used in underground mines to fill voids and stabilize structures. However, its application can lead to severe fire hazards. The foam produces heat through an exothermic chemical reaction, which can ignite surrounding materials. This risk is exacerbated when large quantities are used, as the heat generated can be substantial.

Recent incidents have underscored the severity of this hazard. For instance, a fire in an underground coal mine on June 27, 2024, was attributed to the improper use of polyurethane foam. This incident is not isolated; it marks the fourth such event in four years. These fires pose significant risks to miners’ safety and can lead to extensive damage to mining operations.

To mitigate these risks, it is crucial to follow best practices. Developing a site-specific plan for void fills, using appropriate formwork, and monitoring temperatures are essential steps. Additionally, miners must be trained in the hazards and safety precautions associated with polyurethane foam.

Health Hazards Associated with Polyurethane Foam

Beyond fire risks, polyurethane foam poses significant health hazards. The chemicals used in the foam can cause severe respiratory issues, including asthma and other respiratory diseases. Miners are particularly at risk if they mishandle the foam or fail to use proper protective equipment.

Exposure to these chemicals can lead to immediate and long-term health problems. Symptoms of overexposure include flu-like symptoms, chest tightness, and difficulty breathing. Chronic exposure can result in more severe conditions, such as chronic hypersensitivity and even death.

To protect miners, it is essential to implement strict safety protocols. This includes proper training on the safe use and handling of polyurethane foam, as well as ensuring that miners wear appropriate protective gear. Regular health monitoring and prompt medical attention for any symptoms of exposure are also critical.

Best Practices for Safe Use of Polyurethane Foam

Implementing best practices is vital to ensure the safe use of polyurethane foam in mines. One of the key steps is to develop a comprehensive site-specific plan that addresses all aspects of foam application. This plan should include guidelines for formwork, injection volume, and rates, as well as temperature monitoring and fire watch procedures.

Using the correct type of foam for specific applications is also crucial. Not all polyurethane foams are suitable for filling large voids, as some generate excessive heat. Following the manufacturer’s instructions and safety data sheets (SDS) can help in selecting the appropriate product.

Training is another critical component. Miners must be educated on the hazards associated with polyurethane foam and the necessary safety precautions. This training should cover the proper use of personal protective equipment, safe handling procedures, and emergency response actions in case of exposure or fire.